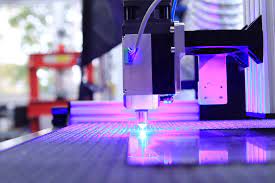

CNC (PC Numerical Control) cutters stand at the forefront of technological advancements in the manufacturing sector, representing the fusion of precision planning and digital innovation. These innovative machines have revolutionized how materials are cut, shaped, and planned, achieving significant upgrades in capability, accuracy, and productivity. This article plunges into the universe of CNC cutters, investigating their sorts, advantages, applications, and the eventual fate of manufacturing with their continued evolution.

The Core of CNC Cutting Innovation

In its middle, CNC cutting incorporates the utilization of PC-controlled machines to conduct various material-cutting tasks. Dissimilar to traditional manual cutting, CNC cutters rely upon digital templates and automated control frameworks, guaranteeing each cut is made with exact precision. This strategy significantly diminishes the margin for mistakes, making it invaluable for businesses where accuracy is paramount.

Kinds of CNC Cutters

CNC Plasma Cutters: Plasma cutters are the most appropriate for cutting heavy metals like steel and aluminum. They work by creating a plasma fly hot enough to mellow the material, offering a balance between speed and accuracy.

CNC Waterjet Cutters: Utilizing high-pressure water mixed in with abrasives, waterjet cutters can slice through virtually any material, from metals to ceramics and stones, without introducing heat-actuated distortions.

CNC Handling Machines: However not cutters in the traditional sense, CNC factories eliminate material with rotary cutting tools to shape the ideal piece. They’re versatile, handling a range of materials including wood, metals, and plastics.

Advantages of CNC Cutters in Manufacturing

Unmatched Precision: CNC cutters produce exact replicas of the digital plan, guaranteeing consistent quality and eliminating human bumble.

Efficiency and Speed: Automated cutting rates up the production interaction, enabling manufacturers to satisfy high needs without sacrificing quality.

Adaptability: CNC machines can rapidly switch between various plans and materials, making them ideal for customized orders or prototyping.

Decreased Waste: Exact cuts mean capable utilization of materials, significantly diminishing waste and cutting down production costs.

Enhanced Safety: Via automating the cutting framework, CNC innovation restricts the gamble of accidents associated with manual handling.

Applications Across Businesses

The versatility of CNC cutters has made them indispensable in various sectors:

Aerospace: Precision is critical in aerospace components. CNC cutters are used to fabricate parts with the exact tolerances expected for safe and powerful flight.

Automotive: From motor parts to custom bodywork, CNC innovation maintains the automotive business’ prerequisite for precision and variety.

Architecture and Construction: CNC cutters play a pivotal work in creating complex architectural components and guaranteeing materials fit impeccably during construction.

Art and Plan: Artists and creators use CNC cutting to rejuvenate intricate plans, whether in metal models, woodwork, or custom decorations.

In conclusion

CNC cutters address a significant leap forward in manufacturing innovation, offering unmatched precision, viability, and versatility. As these machines continue to create, they commit to continue to push the boundaries of what’s conceivable in manufacturing, planning, and beyond, establishing their status as indispensable tools in the advanced industrial landscape.

FAQs

What materials can CNC cutters handle?

CNC cutters can handle countless materials, including metals, plastics, wood, glass, and composites. The kind of CNC cutter used (laser, plasma, waterjet, or handling machine) will depend upon the material’s properties and the ideal completion.

Are CNC cutters suitable for small businesses?

Absolutely. The scalability and versatility of CNC cutting innovation make it suitable for businesses, things being what they are. Small businesses can benefit from the ability to convey top-caliber, custom things with minimal waste and decreased labor costs.

How do CNC cutters contribute to sustainability?

CNC cutters enhance sustainability by decreasing material waste through exact cuts and capable utilization of assets. Additionally, their ability to create parts on demand diminishes the prerequisite for large inventory stocks, cutting down the carbon impression associated with storage and transportation.

READ MORE ON: Baddiehub