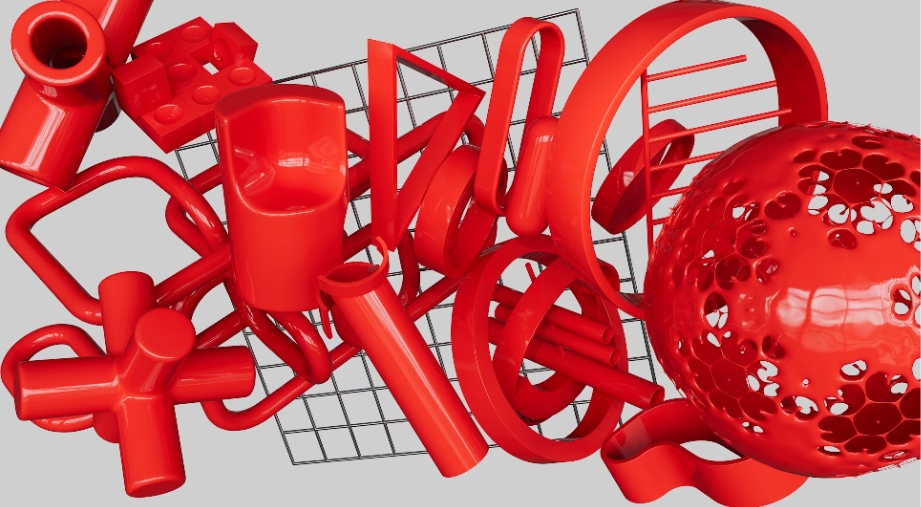

In a world teeming with diverse products, the unsung hero behind many of our everyday items is the injection moulding process. This intricate and fascinating technique, brought to life by expert mould suppliers, shapes much of what we see and use in our daily lives. From the smartphone in your pocket to the chair you sit on, injection moulding has a hand in creating these ubiquitous objects. Let’s unveil the hidden world of this remarkable process and the innovations mould suppliers contribute to our everyday experiences.

The Essential Role of Mould Suppliers

Mould suppliers are the backbone of the injection moulding industry. They craft the precise moulds needed for producing millions of items worldwide. Their expertise in designing and manufacturing moulds allows for the creation of complex, high-quality products with remarkable efficiency. The meticulous work of these suppliers is crucial in transforming a simple concept into a tangible, functional product.

How Injection Moulding Shapes Our Daily Lives

The impact of injection moulding on our daily lives is enormous. This process is responsible for creating a vast array of products, from household appliances to medical devices. Its ability to produce large volumes of parts with consistency and precision makes it a preferred choice for many industries. The versatility and efficiency of injection moulding are what make it such an integral part of our daily existence.

Technological Innovations

In recent years, innovations in injection moulding have been remarkable. Mould suppliers are continually pushing the boundaries of what can be achieved with this technology. From incorporating biodegradable materials to using more energy-efficient processes, these innovations not only improve the quality and diversity of products but also contribute to a more sustainable future.

The Strong Synergy

The relationship between an injection moulding company and its mould supplier is pivotal. This synergy is essential in ensuring that the end products meet the highest standards of quality and functionality. A reliable injection moulding company, working closely with skilled mould suppliers, can bring about innovations that redefine product design and efficiency.

The Future Trends

Looking to the future, the injection moulding industry shows no signs of slowing down. Trends such as automation, 3D printing, and advanced materials are shaping the future of this field. Mould suppliers are at the forefront of these changes, adapting and innovating to meet the evolving demands of various industries.

Sustainable Practices

Sustainability in injection moulding is becoming increasingly important. Mould suppliers are playing a critical role in this shift by adopting more eco-friendly materials and processes. This move towards sustainability is not just beneficial for the environment but also meets the growing consumer demand for greener products.

In conclusion, the world of injection moulding, powered by the expertise and innovation of mould suppliers, remains largely unseen yet is incredibly impactful. This process is a cornerstone of modern manufacturing, touching almost every aspect of our lives. As technology evolves, the role of mould suppliers and injection moulding companies will continue to grow, shaping the future of manufacturing and beyond.