Introduction:

The word VFD stands for variable-frequency drive. It is an electronic tool used for controlling a motor’s speed. By verifying the torque of an electrical motor, it varies the frequency and the voltage supplied to the engine. A tool like a variable-frequency driver saves energy and improves the performance of industrial and commercial applications while controlling the speed of the motor. We commonly observe variable-frequency drivers on HVAC systems, fans, pumps, and other machinery objects that require a variable-speed operator. Energy consumption is rising in India. So the demand for energy-effective technologies is increasing contemporaneously. It is a surprising fact to know that India is the third-largest country in the world that generates electricity coincidentally every time. Between the financial years 2022-2023, India has constructed 1844 TWh of electricity. It is a large number, certainly. Among these numbers, 1618 TWh was generated by the utilities. And in 2023, the gross consumption of electricity per capita in India was 1327 kWh. This article will examine the importance of executing tenders for VFDs in India while observing their various dynamics.

Annual Assessment of VFD Tenders:

In India, the periodic analysis of variable frequency drive tenders reveals a growing trend toward energy effectiveness and automation in commercial sectors. With the optimization of performance and reducing energy consumption, the demand for VFDs in industries, that control the speed of electric motors has increased steadily. Government agencies that promote energy effectiveness and sustainability, couple themselves with innovative technologies. They have further fueled the relinquishment of VFDs across several sectors, such as manufacturing, agriculture, and infrastructure development. This analysis indicates a competitive demography between domestic and international players that are vying for tenders. Companies offering innovative results with features like remote monitoring, prognostic maintenance, and compatibility with renewable energy sources have gained traction with the market. There were 814 VFD tenders published in India last year. The state Tamil Nadu steals the first position among all other states while issuing 97 tenders. Furthermore, Uttar Pradesh implies 71 tenders, followed by Odisha with 66, Andhra Pradesh with 60, Maharashtra with 58, and Haryana with 55. The Indian Oil Corporation Limited took the first position by announcing 59 proposals. Similarly, 47 contracts were released by the National Aluminium Company Limited.

VFD tenders for purchase:

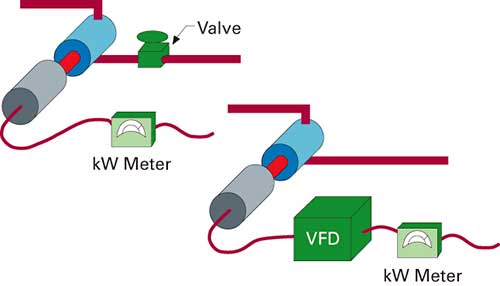

A VFD is a device used in a drive system comply with the following three main sub-systems: the AC motor, the main drive regulator assembly, and the drive or driver interface. VFDs are used in operations ranging from small appliances to large compressors. Systems that use VFDs can be more effective than hydraulic systems, similar to systems with pumps and mute control for fans. There are three main ingredients in a VFD, they are respectively a rectifier, a DC link, and an inverter. In industrial organizations, the utilization of the most common types of VFDs are Voltage-Source inverters (VSI), Current-Source inverters (CSI), and pulse width modulation inverters (PWM). VSI is the most common type of VFD, where a simple diode circuit is used to get the DC signal from the AC signal and has a capacitor that stores energy. In the purchase phase, manufacturers or suppliers supply the variable frequency drives. After that, government bodies, utilities, or large associations invite tenders from eligible vendors. The key considerations in these tenders include the specialized specifications of the VFDs, similar to power conditions, voltage compatibility, and effectiveness norms. Also, factors like after-deal service, bond vittles, and compliance with non-supervisory morals are pivotal. Out of 814 tenders, 9 tenders were being published for the purchasing processes of the variable frequency drivers. Approximately 143 organizations came forward to implement the VFD offerings. NLC India Limited, Neyveli Lignite Corporation, has introduced a purchase notice for an AC drive spare digital. RCDF-MD in Rajasthan issued a purchase tender notice for a 110KW VFD compressor.

VFD tenders for procurement:

Procurement encircles the installation and integration of variable frequency drives into existing systems or new systems. The contractors or system integrators can execute the installation process efficiently in the procurement stage. To execute this process, the tender documents should outline project conditions, timelines, and performance prospects, and the contractors must demonstrate expertise in VFD installation, programming, and commissioning to qualify for the tender. Furthermore, agreement with safety protocols and environmental regulations is vitally important. In the procurement stage, the main aim is to ensure flawless deployment of VFDs while minimizing dislocations to operations. As stated on the record, 123 bids were proposed for installation processes, and 51 offers were made for procurement purposes. For example, the Department of Defence Production in Maharashtra advertised a custom bid for services such as supply installation commissioning of 75 KW 100HP and 142 AMPS 3-phase variable frequency drive for a pump. Another example shows that the Indian Oil Corporation Limited in Gujarat proposes a procurement tender notice for medium voltage variable frequency drives with FCS panels and without a sync bypass facility.

VFD tenders for annual maintenance:

Among the 814 tenders proposed by the various agencies, 14 were issued for the annual maintenance of variable frequency drivers in India. For illustration, National Thermal Power Corporation Limited in Andhra Pradesh advertised a tender for biannual maintenance of Danfoss VFDs installed at AHP and NTPC Solapur. Besides, the Indian Oil Corporation Limited in West Bengal invited a non-comprehensive annual maintenance contract for Siemens VFD installed at PHDPL Haldia through M/s Yantra Harvest Energy Private Limited.

VFD tender budget estimation:

In India, the government spends a huge amount of money to promote VFD tenders. According to statistics, few agencies publish their tender budget with the notice. As an example, we can show that the Indian Oil Corporation in Odisha has spent 19.19 lakhs for an annual maintenance VFD contract. Whereas, the Indian Oil Corporation in West Bengal published a tender notice for annual maintenance of variable frequency drivers with a budget estimation of 12.76 lakhs. Another example is the Madhya Pradesh Power Generating Company spending 21.68 lakhs on the procurement of Seimens Variable Voltage Frequency AC Drive for 2×600 MW, PH-I, CHP, and SSTPP Dongalia. Furthermore, the Security Printing and Minting Corporation of India Limited in West Bengal spent 13.16 lakhs on the procurement tender for the Micromaster 440 Drive for Coining Presses.

Live tender analysis:

As recorded on the online proposals on April 10, 2024, it is evident that 20 tenders were advertised for the implementation of variable frequency drives in India. In this, Andhra Pradesh was ranked at the top with 7 bids, followed by Tamil Nadu with 6, Uttar Pradesh & Bihar at 4 each, Rajasthan with 3, Gujarat with 2, and Karnataka with 1.

Conclusion:

Organizations that purchase variable frequency drives at competitive prices have cheaper functional costs and reduced environmental footprints through utilizing appropriate bidding customs. Through the successful implication of scrupulous planning, strict evaluation criteria, and robust project management practices, India can continue its journey toward energy security and environmental supervision. So the proper investment in VFDs through effective tender applications can play a pivotal role in achieving these objectives.